|

Automatic Rotary Forging Machine for Making Cone from Welded Pipe China

Rotary Forging Machine for Making a Cone on a Pipe from China

Automatic Rotary pipe reduction machine of this type ( it is also called a machine for making a cone on a pipe

, pipe end taper machine

, pipe taper machine

, pipe shrinkage machine for cone

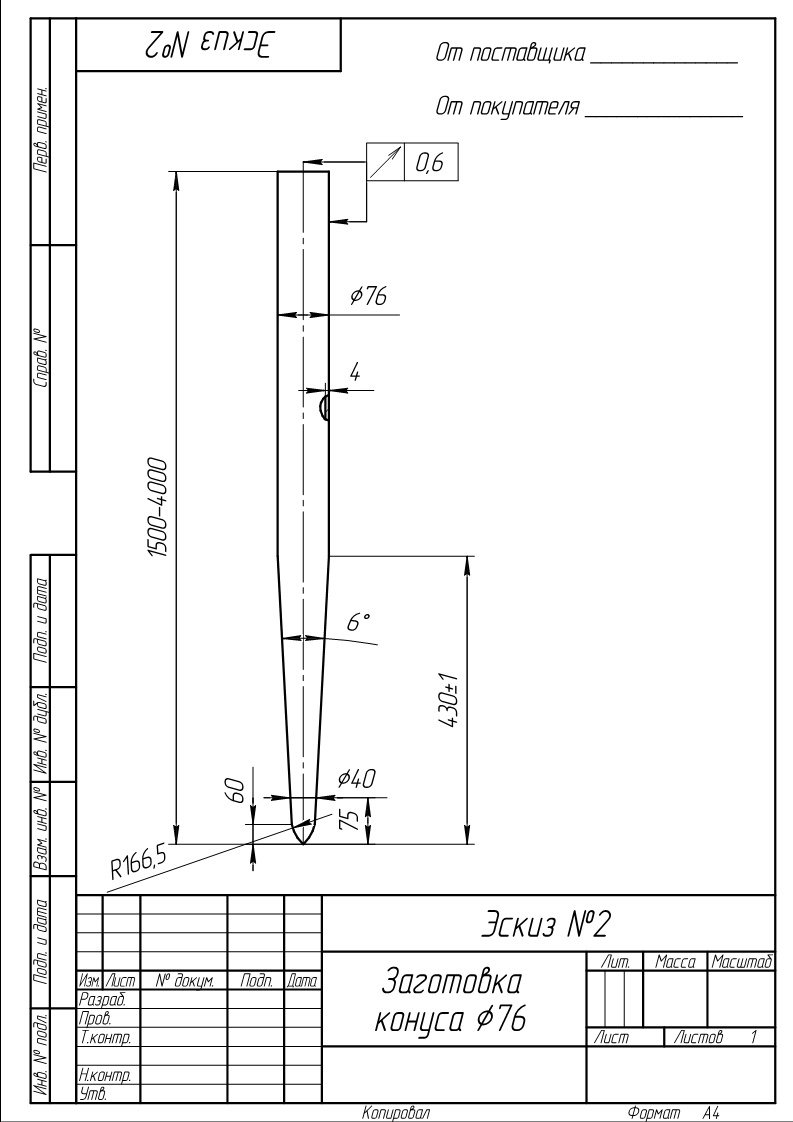

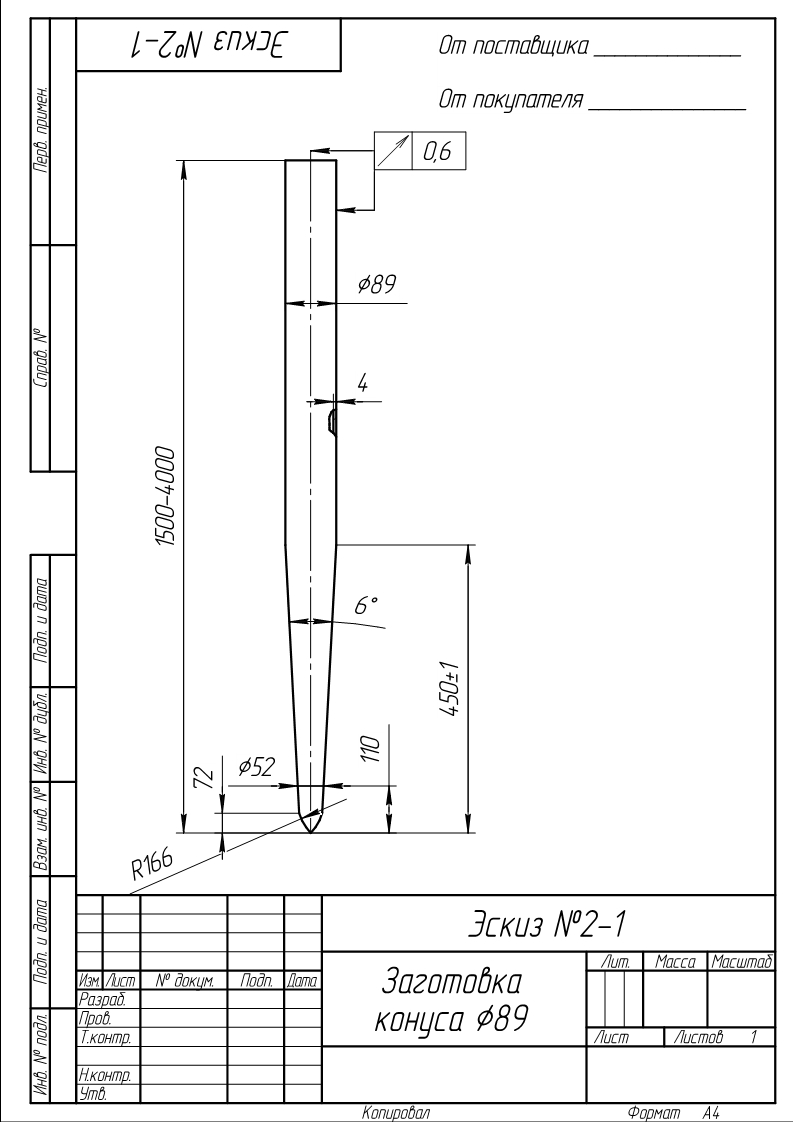

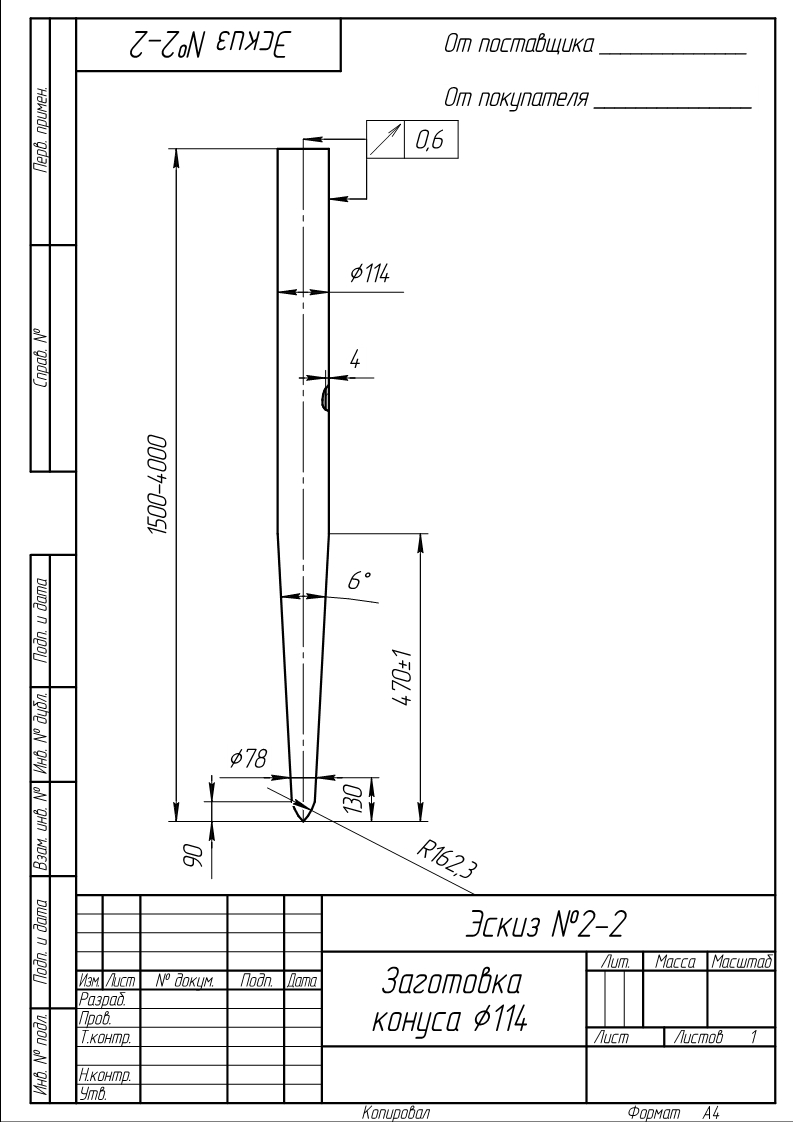

and so on) is capable of processing a pipe for the manufacture of conical endings by sequential four-sided stamping with a diameter of 57, 76, 89, 114 mm and other sizes. The maximum length of the processed surface is up to 600 mm, the maximum pipe thickness is up to 5 mm, As part of a tool kit for pipes with a diameter of 57, 76, 89, 114 mm (optional), which is made of tool steel for punches and dies, the best imported Japanese tool steel, which can process more than 100,000 pieces of blanks. The creation of the cone is carried out by the method of hot forging due to special equipment. Due to the additional tool, the clamping and feeding of the workpiece (pipe) into the working head occurs automatically. The operator only needs to change the pipes at the right time.

It should be emphasized that the effective tip length on our machine of the processed workpiece will reach up to 600 cm, such a tip length is convenient for automotic welding of spirals to the pipe on the machine, and the long tip is more susceptible to corkscrew.

The machine is used specifically in the production of screw piles and multi-turn and blade, pipe taping is performed by hot metal forging in just 10 seconds. The deformation occurs gradually, the tooling acts evenly on the workpiece from all sides. The principle of operation of the machine to create a cone on the pipe is as follows: inside the working head there is a rotor with strikers that act on the tool itself, with constant short-term steps, the tooling comes into contact with the pipe and at the output we get a cone on the pipe. As a rule, in order to obtain symmetrical products, the rotor with strikers rotates around the pipe. Due to the specifics of the equipment, finished products are obtained like polished ones.

Advantages of our rotary pipe reduction machine:

Features:

The closed circulating lubrication system guarantees the machine uninterrupted operation for a long time.

The resulting products have a smooth, high-strength working surface

<After processing, the arc degree on the pipe meets the technical conditions for further welding work on our rotary welding machine for the manufacture of multi-turn screw piles krinner

The machine has a simple operation

High productivity of 1000-3000 pcs in 8 hours (depends on the diameter and thickness of the workpiece)

Exact repeatability of products

Stability and strength of the machine itself, the large weight of the machine ensures stable operation of the taper

Power, high efficiency

Minimum friction, since the tool acts in short-term steps, this affects the quality of the product;

Quick change of tooling (segments made of high-quality tool metal) - tool replacement and adjustment of the rotary forging machine takes the operator several minutes;

High quality of products — due to the uniform stretching of the pipe, the quality of the final product is at a high level.

The warranty period for the rotary forging machine is 18 months and is calculated from the date of delivery of the equipment to the warehouse of the consignee.

The technology of our rotary forging machine is considered to be the latest in recent years, the technology of the machine is better than other Chinese suppliers, although in fact there are few of them, our machine has an advantage in price and quality, too, and all this saves a lot of labor and time.

| Technical parameters of the rotary forging machine MSRF-7 |

| Diameters of the forged workpiece(mm) |

57,76,89,108,114 and others |

| Maximum length of workpieces(mm) |

4000 |

| Maximum processed length of the end of the workpiece (mm) |

550 |

| Maximum wall thickness of the workpiece(mm) |

7 |

| Number of strikers in the composition |

1-5(by agreement) |

| tooling resource |

more than 100,000 pieces of workpiece |

| The accuracy of the resulting forging(mm) |

±0,2 |

| Type of steel for the riveted pipe |

VSt3KP2 or VSt3PS2 GOST 380/ ISO 630Fe360A/ DIN EN 10025 Fe360B |

| Power(kv) |

22 |

| Cone forming speed(sec) |

5-10 |

| Machine weight (depending on the configuration)(kg) |

5000 |

| Power Supply Requirement |

380V/50Hz/3 phase |

| Pneumatics Requirement(MPa) |

0.5 |

| Pipe connection to lubricating oil (liter) |

minimum 100 |

| Dimensions LxWxH (mm) |

4500x1200x1750 |

| Description of the machine |

The principle of operation of the machine is sequential four-sided stamping of large-sized pipes. taping takes place thanks to special equipment by hot forging. |

The following machines: 3 different models of a rotary forging machine for making a cone of different lengths from a welded pipe for the production of screw piles, in the middle of the gray picture is the MSRF-7 model, which will be able to produce almost all sizes of screw piles on the market 57,76,89,108, 114 and others, only the tooling needs to be replaced.

Rotary welding machine for the manufacture of multi-turn screw piles krinner (Machine for welding spirals to the pipe)...

|

|

|

| machine for making a cone on a pipe from China |

machine for making a cone on a pipe from China |

machine for making a cone on a pipe from China |

|

|

|

| machine for making a cone on a pipe from China |

machine for making a cone on a pipe from China |

machine for making a cone on a pipe from China |

|

|

|

| machine for making a cone on a pipe from China |

machine for making a cone on a pipe from China |

machine for making a cone on a pipe from China |

|