|

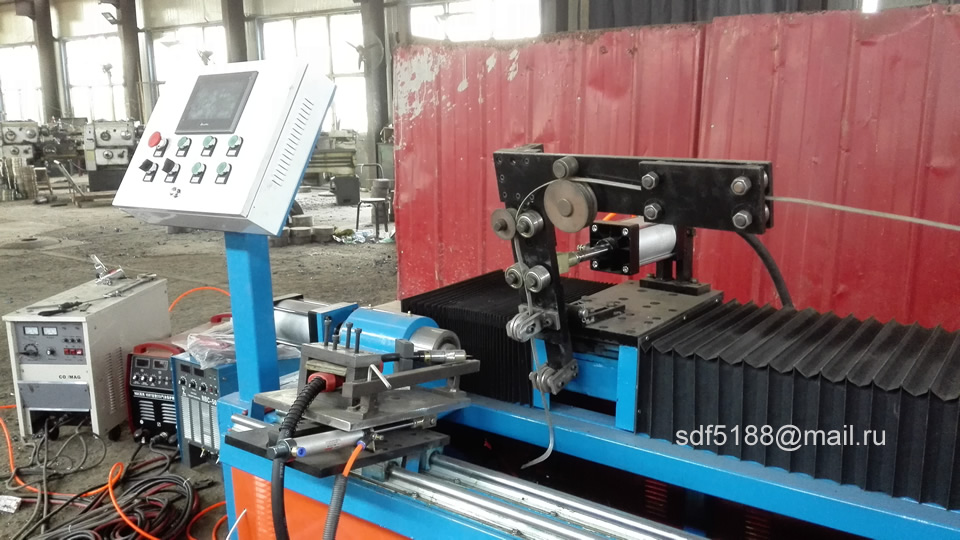

Welding Equipment for Screw Piles , Rotary Welding Machine for the Manufacture of Multi-turn Screw Piles krinner from China

Welding equipment for welding spirals to a pipe, rotary welding machine for making multi-turn screw piles is the latest technology for the production of multi-turn screw piles, previously factories used a universal welding rotator and welding robot for welding, or manually, for this you need to manufacture a spiral separately, as soon as our machines appeared on the market, they immediately began to be in demand, especially in factories exporting their screw piles to Japan, Russia, Europe, and Southeast Asia, since it saves a lot of labor.

The set of the machine includes a rotary welding machine for welding into the pipe, a CNC control panel, a pneumatic system, a welding machine for spot welding and a wire welding machine (optional), a rotator (unwinder) for steel tape (the recommended spiral size is 10mm wide or 12mm 2mm thick).

| Automotive rotary welding machine MSRW-5 |

| Pipe diameters for welding(mm) |

57, 76, 89,108,114,157 and others |

| Maximum length of pipe for welding(mm) |

4000 |

| Maximum welding length(mm) |

1500 |

| Width and thickness of the welded spiral tape (mm) |

10-15 x 2 |

| The pitch between the screws of the welded tape(mm) |

40-50-60 |

| Maximum welding speed (welding length per minute)(mm) |

800 |

| Power (kv) |

4 |

| Machine weight (kg) |

1000 |

| Dimensions (length width height)(mm) |

6300x1100x1500 (divided into 2 parts for the convenience of shipping to the container) |

| Power supply requirement |

220V /50Hz/3 phase |

| Welding machine requirement |

400A/380V/50Hz/3 phase |

| Description of the machine |

Is used in the production of multi-turn screw piles krinner for welding the spiral on the pipe |

Rotary Forging Machine for Making a cone from welded Pipe China (rotary forging machine for forming a cone at the end of the pipe)...

|

|

|

| Welding Equipment for the Production of Screw Piles from China |

Welding Equipment for the Production of Screw Piles from China |

Welding Equipment for the Production of Screw Piles from China |

|

|

|

| Welding Equipment for the Production of Screw Piles from China |

Welding Equipment for the Production of Screw Piles from China |

Welding Equipment for the Production of Screw Piles from China |

Multi-turn screw piles: multi-turn screw piles - drill-screwed piles - piles of the “krinner” type (“krinner”). The modern and technological design was originally developed by the German company KRINNER Schraubfundamente GmbH and with great success began to be used in Europe.

After the name of the largest manufacturer, such piles began to be called "Krinner piles”, and the name of the company Krinner became a household name (Xerox). In fairness, it should be noted that multi-turn screw piles are produced not only by Krinner - piles of this design are produced in the USA, Korea (ACG), China (mostly for export to Japan and Russia). Little is known about the Russian manufacturers of drill screw piles, including our customers.

A multi-turn pile usually has a cone-shaped trunk on which a multi-turn spiral is located. Blades of small diameters make such a pile look like an ordinary self-tapping screw on wood (of course, on the appropriate scale). And the principle of operation of such a screw pile is very similar to a self-tapping screw - the conical trunk pushes and compacts the soil, and the small diameter of the blades allows you to screw the pile with little effort. Due to the fact that the Krinner pile spiral has a large number of turns that are tightly fixed in the compacted soil, the bearing capacity of such a pile is very high.

The head of the criner pile can have various designs - in the form of a flange, a bracket for fixing wooden structures or a lock for mechanized screwing.

Features of multi-turn screw piles krinner:

High load-bearing capacity. Due to the conical shape of the trunk, the multi-turn pile seals the soil as much as possible, and other things being equal, it is the leader in the ratio of the diameter of the trunk to the bearing capacity.

High corrosion resistance. The original kriner piles are covered with a thick layer of zinc, capable of resisting the most aggressive environmental factors for many years. The thick walls of the pile trunk also contribute to a long service life. However, when copying technology, the quality often suffers, so when choosing a pile, pay attention to the manufacturer's level and the quality of the coating.

Ease of installation. A set of standard solutions and a finished product in the form of a pile assembly with a head makes the use of the krinner pile very convenient and simple, and the absence of the need to trim its trunk and weld the head does not require welding and subsequent protection of welding joints from corrosion. The ease of screwing was mentioned above.

|